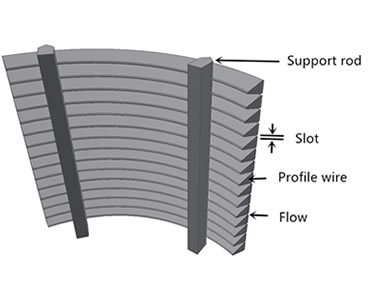

The Sieve Bend Screen, also known as the DSM screen, is a curved wedge bar screen crafted from wedge wires(V wires ).

This ingenious sieve bend screen offers a vital and highly effective solution for screening, dewatering, classification, and separation in heavy minerals processing applications. What sets it apart is its self-sufficient operation, requiring no power (unless equipped with a tilting system), making it a cost-effective, quiet, and efficient component in your screening process.

Tailored to your specific needs, Sieve Bend Screens can be manufactured in various widths, arc lengths, apertures, or wedge wires to match the flow rate and material being separated. While most applications call for Static Sieve Bends, we also offer the versatility of "Cross Flow," "With Flow," and "Vibrating" Sieve Bends.

The beauty of the sieve bend screens is in its simplicity—a fixed section of a wedge-bar screen bent to an arc.

Enhance your screening process with the efficiency and adaptability of Sieve Bend Screens - the ideal choice for your separation needs.

1. Find efficiency and separation with all sizes of quality Sieve Bends

2. Quality-crafted Sieve Bends in all sizes, suitable for a range of screening media3. Quick and Easy Installation

4. The oversize product is distinctly wetter than that obtainable with vibrating screens or high-speed shakers.

5. Wedge wire sieve bend screens have great capacity than the traditional vibrating screens.

6. Wedge wire is the optimum dewatering screen, Polyurethane screens are a cost-effective screening solution. Sieve bend screens in both polyurethane and wedge wire to provide the most efficient solution for your plant.

7.Easy separation of solids from slurry

Choose the perfect solution for your diverse applications in quarries, minerals, agriculture, food processing, wood chip, or wastewater with our wide range of special Sieve Bend screens designed. These arc Sieve Bend screen filters are highly reliable and efficient in separating fine solids from the slurry, catering to various use cases.

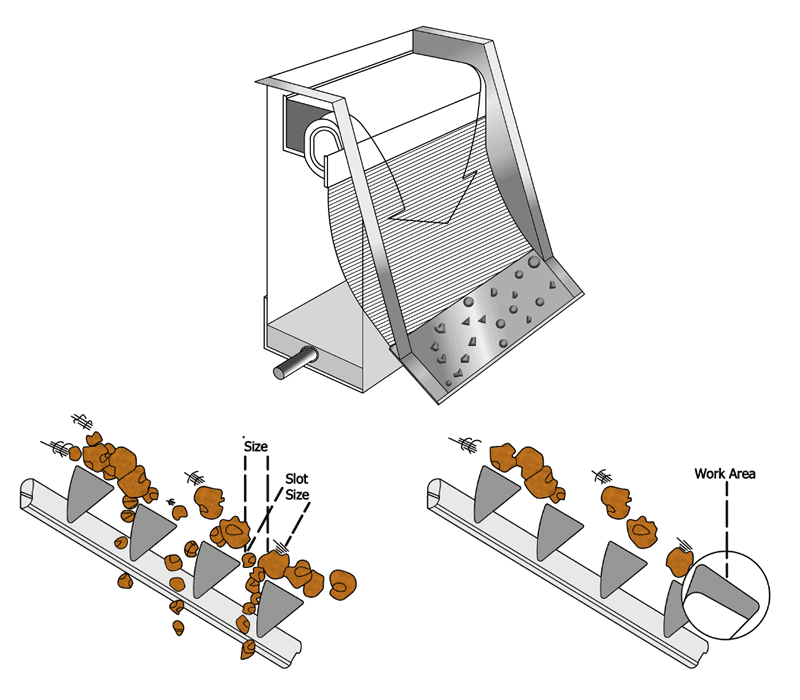

Slurries are fed into the sieve bend through the feed box, where they overflow onto the screen. This process effectively separates water and smaller particles from larger ones, allowing the latter to travel down the screen surface while most of the liquid is drained away.

In a typical feed scenario, the leading edge of the wedge wire efficiently removes water and fine particles, passing them through the screen until they reach the cut point size. Meanwhile, oversized particles continue to move across the top of the screen. The beauty of Static Sieve Bend screens in their low maintenance requirements and ability to function effectively even with small head heights.

The DSM Sieve bend screen excels in sizing and dewatering applications, effectively removing solids from liquids or facilitating solid/solid separation in dry feed situations. The curved surface structure of the sieve bend screen offers significant advantages over flat panels made of wedge wire screens, including higher flow rates, increased capacity, and superior filtering capabilities.