Basic Company Information

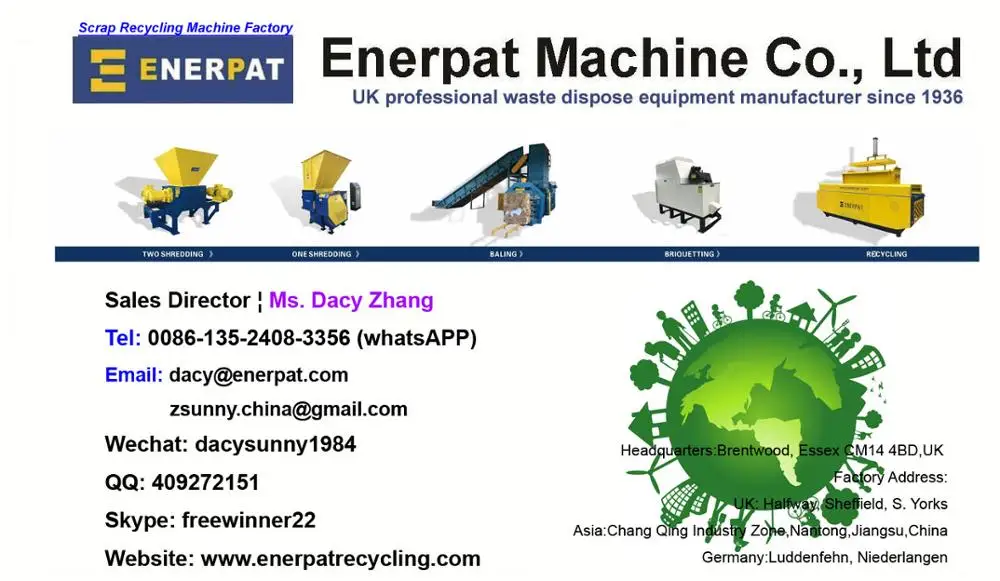

Enerpat Machine Co., Ltd

Enerpat Machine Co., Ltd

TEL : 86-513-87789920 / FAX : 86-513-87782755

Xintai Roard No.2 Jiangsu Nantong China [CN]

Homepage : http://www.enerpatrecycling.com

Main Products

scrap metal baler , metal baler , metal baling machine , metal shredder , double shaft shredde

Company Advantage

we are professional manufacturer of kinds of recycling plant, the member of Enerpat Group in UK since 1936.

Company Advantage

ENERPAT is a British multinational engineering and recycling company headquartered in London and Manchester. It is UK' S largest engineering company and maker of scrap recycling equipment and its recycling plant, which generates about 12 percent of the company' S total sales, is its second-most profitable unit behind the industrial automation division

Enerpat' Principal activities are in the fields of industry, energy, environment and recycling. It is organized into three main divisions: Industry, Energy, recycling, Enerpat and its subsidiaries employ around 50, 000 people across nearly 20 countries and reported global revenue of approximately EURO 28.3 billion in 2012. The company has been the subject of a number of controversies in its history.

Enerpat offers a wide range of recycling engineering- and scrap processing-related products and services. Its products can be broadly divided into the following categories:

Car Recycling Plant, Tyre Recycling Plant, E-Waste Recycling Plant, Municipal waste recycling plant. Waste Shredders, Waste Balers, And Waste Machines. And transportation and logistics-related products

Nantong Enerpat Machine Co., Ltd is the wholly owned subsidiary of ENERPAT

Which also Enerpat' ' S Asia production base.

Detail Company Introduction

ENERPAT is a British multinational engineering and recycling company headquartered in London and Manchester. It is UK' S largest engineering company and maker of scrap recycling equipment and its recycling plant, which generates about 12 percent of the company' S total sales, is its second-most profitable unit behind the industrial automation division

Enerpat' Principal activities are in the fields of industry, energy, environment and recycling. It is organized into three main divisions: Industry, Energy, recycling, Enerpat and its subsidiaries employ around 50, 000 people across nearly 20 countries and reported global revenue of approximately EURO 28.3 billion in 2012. The company has been the subject of a number of controversies in its history.

Enerpat offers a wide range of recycling engineering- and scrap processing-related products and services. Its products can be broadly divided into the following categories:

Car Recycling Plant, Tyre Recycling Plant, E-Waste Recycling Plant, Municipal waste recycling plant. Waste Shredders, Waste Balers, And Waste Machines. And transportation and logistics-related products

Nantong Enerpat Machine Co., Ltd is the wholly owned subsidiary of ENERPAT

Which also Enerpat' ' S Asia production base.

Detail Company Introduction

ENERPAT GROUP is the international company,we based in Uk,we have factory in Uk,Germany,and China,we also have Enerpat Australia sales company. We focus on Metal Balers,Wate Shredders,Recycling Plant And Alligator Shears.

Factory Information

Factory Location

Factory Address

Jiangsu Nantong Rugao Industrial Zone

Factory Size

3,000-5,000 square meters , Above 50 People

No. of R & D Staff

5-10 People

No. of Production Lines

10

Annual Output Value

US $50 Million - US $100 Million

Trade Information

Total Annual Sales Volume

Above US $100 Million

Export Percentage

81% - 90%

Accepted Delivery Terms

FOB , CIF , EXW

Accepted Payment Currency

USD , EUR , CNY

Accepted Payment Type

T/T , L/C , PayPal , Western Union