Stucco, plaster and veneer would easily crack under types of stress and deflation in the process of building construction and residential living. Metal lath is used to prevent or decrease wall crackings in either pumped or troweled application. Sheet metal lath is slit and expanded into small diamond openings (approximately 11,000 per square yard).

We supply sheet metal lath in two types: diamond metal lath and rib meta lath. Flat diamond metal lath is nor used over solid surface like gypsum, concrete and wood sheathing. Because flat sheet will only cause the stucco to bond only to the sheathing and not complete the embedding process. Therefore expanded metal mesh is usually self-furred: dimpled and V-grooved. Diamond metal lath, for its unravel feature, is especially suitable for high strength needed architectures. Rib metal lath is expanded metal made sheet with ribs to increase the strength of it overall structure. Strip lath and corner lath are also available for installation convenience.

Flat diamond metal lath could only bond to the sheathing but not complete the embedding process for covering a solid surface like gypsum, concrete and wood sheathing. Therefore self-furring metal lath came into being. Self-furred diamond metal lath is generally used as reinforcement of plaster for solid surface. And it is divided into two types: dimpled and V-grooved. The two kinds of diamond metal lath is showed below in DML-01 and DML-02.

SML-01: Diamond metal lath with dimples shapes.

SML-01: Diamond metal lath with dimples shapes. SML-02: Diamond metal lath with V grooves.

SML-02: Diamond metal lath with V grooves. SML-03: Plan and section of diamond metal lath with dimples shapes.

SML-03: Plan and section of diamond metal lath with dimples shapes. SML-04: Plan and section of diamond metal lath with V-grooves.

SML-04: Plan and section of diamond metal lath with V-grooves. SML-05: diamond metal lath LWD: 17.7 mm, SWD: 8.3 mm.

SML-05: diamond metal lath LWD: 17.7 mm, SWD: 8.3 mm.Specification

Application:

Rib lath is the most rigid for all sheet metal laths for its ribs running the whole length of the sheet added additional strength. Rib metal lath is commonly used for soffits and ceilings. Two types of rib metal lath are supplied: Hi-rib lath and flat rib lath, among which the most popular type is 3/8" high rib and 3.4 lbs./sq. yd.

Flat-Rib: 1/8" for all ribs on the lath, spaced at 3" on-center. The 3" wider space is provided for wooden or metal supports. This lath is ideal for machine applied plaster, backed with 2 strips of backing papers.

Hi-Rib Lath: 1/8" rib between two 3/8" ribs, spaced 4" every pairs of 3/8" ribs. Hi-Rib lath is used primarily in horizontal applications or for framing spaced no more than 24" on center. Strips of 3" backing paper should be attached to the spaces between the 3/8" ribs in order to minimize blow through of plaster when machine applied as showed below in picture SML-09.This lath should be installed horizontally on vertical walls or ceilings.

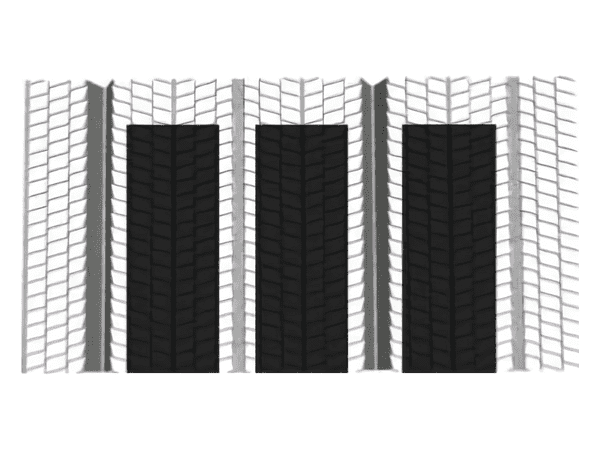

SML-06: Hi-Rib Lath with 3/8" ribs and 1/8" ribs in the middle of 3/8" ribs.

SML-06: Hi-Rib Lath with 3/8" ribs and 1/8" ribs in the middle of 3/8" ribs. SML-07: Flat rib lath with widths of two opening holes being 1'.

SML-07: Flat rib lath with widths of two opening holes being 1'. SML-08: Hi-Rib Lath with widths of two opening holes being 1'.

SML-08: Hi-Rib Lath with widths of two opening holes being 1'. SML-09: Strips of 3" backing paper should be attached to the spaces of 3/8" ribs with margin.

SML-09: Strips of 3" backing paper should be attached to the spaces of 3/8" ribs with margin.Specification

SML-10: Rib metal lath would be bound together tightly for the transport security.

SML-10: Rib metal lath would be bound together tightly for the transport security.Application

Made of expanded metal, rib lath is the ideal material as a background for plaster, render, stucco application in construction of suspended ceilings partition.

SML-11: A roll of strip lath used for areas prone to crack.

SML-11: A roll of strip lath used for areas prone to crack.Strip lath is expanded diamond metal lath formed into strips with smooth edge and used for reinforcing joints of solid based. It is normally attached diagonally at the corner of all openings as doors, windows or areas prone to crack for reinforcement. It may also be used to span pipe chases or reinforce other stress points such as the corners of openings in the stucco membrane within the lath system.

Specification:

Roll size:

Packaging:

Corner lath came into being by strip lath bent into obtuse angle with smooth edges. It is used in where intersections happens—wall meet walls or ceilings and ground.

| Design | Flange width | Length | Pieces per carton | Feet per carton | Galvanized weight per 1000 lineal. feet |

|---|---|---|---|---|---|

| CL-01 | 2" | 96" | 75 | 600 | 84 lbs. |

| CL-02 | 3" | 96" | 75 | 600 | 118 lbs. |

| CL-03 | 2" | 48" | 125 | 500 | 84 lbs. |

SML-12: Galvanized carbon metal made corner lath.

SML-12: Galvanized carbon metal made corner lath.Feature

Application

Accessories:

Installation

Metal lath products that include the water resistant barrier, shall be installed horizontally on vertical walls with the upper layer lapped over the lower layer not less than 2 inches and vertical joints overlapped no less than 2 inches.

Where paper-backed metal lath is applied over wood based sheathing for cement plaster (stucco) reinforcement, an additional layer of Grade D paper shall be installed on the sheathing.

Codes and standards