wire drawing dies from TC or PCD

1/General introduction of tungsten carbide wire drawing dies

Structure name for tungsten carbide drawing dies

The roles of different parts for tungsten carbide drawing dies blanks

The shape and size of different parts for carbide drawing die, depended on the drawn metal components, performance and size, the size for compression ratio, lubrication, drawn conditions and requirements for products.

Entrance area

Entrance area to work area are designed for arc transition in favor of material drawing into the work area, and will not grazed by ridge hole.

The cone angle of lubrication

Lubrication area is the storage of lubricants, so the the material is drawn can be lubricated, in favor of the smooth progress of the drawing process. It’s by means of lubrication area to enlarge the work area when drawing die enlarge hole. The height for lubrication size is 0.25 times higher than the height of blank.

Work area

Plastic deformed area of metal stretch, that is metallic materials is through the area, diameter will range from big to small, tube wall becomes thin or tube diameter gets small when drawing tube. The length of the work area will be different according to drawn material diameter and lubrication. The principle for choosing is as following:

1.Drawing soft metal wire should be shorter than hard metal wire

2.Stretching small metal wire should be shorter than dry lubrication stretch

3.Wet lubrication stretch should be shorter than dry lubrication, in normal cases, the length of the work zone is 1.0-1.4 times than wet diameter of sizing district

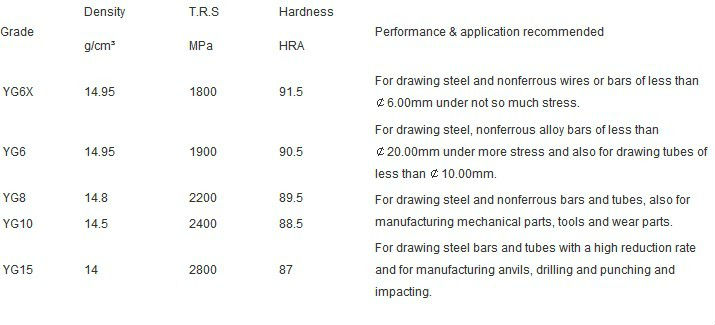

2/GRADE AND SPECIFICATION OF DRAWING DIES

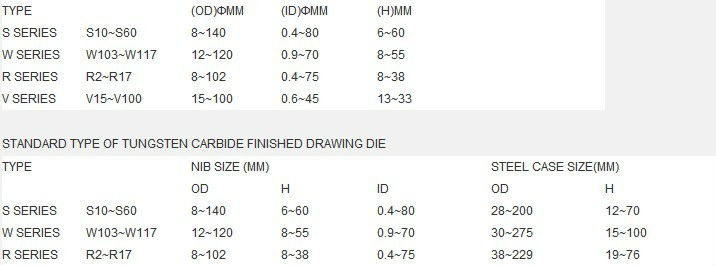

3/ REFERENCE SIZE OF STANDARD TUNGSTEN CARBIDE WIRE DRAWING DIE

4/ PRODUCTION OF TUNGSTEN CARBIDE WIRE DRAWING DIES

5/ STANDARD PACKAGE OF THE TUNGSTEN CARBIDE WIRE DRAWING DIES

6/ CERTIFICATE OF ZHUZHOU UKO

.....

.....

7/ SERVICE OF ZHUZHOU UKO

1. feedback within 24 hours;

2. good english communication;

3. professional suggestion on product;

4. good traning export sales person;

5. skilled in tungsten carbide sell;

6. could issue the C/O(certificate of origin)to customer to reduce the tax;

7. could accept all payment terms of T/T(both in advanced and after shipment), D/P, D/A, L/C, western union, paypal and etc;

8. could offer free samples below 0.5kgs under the condition of freight paid by customer;

9.MOQ 5kgs for sintered blank.

ZHUZHOU UKO CEMTNED CARBIDE CO.,LTD.

Address: Xinhua West Road, Hetang district, Zhuzhou, Hunan, P.R.China .

Postal code: 41200

Tel: +86-731-28821507

Fax: +86-731-28821527

Mobile: +86-14773337630

Website: www.ukocarbide.com

Skype: +86-14773337630