What are the specifications about date code insert?

| Product | Date Code Insert and Cooling System for Injection Mold |

| Model No. | CO |

| Material | S136 |

| Net weight | 1-49.5g/PCS |

| Grinding Precision | 0.001mm |

| EDM Precision | 0.002mm |

| Surface Roughness | Ra 0.025 |

| Process | CNC machining,turning,milling,drilling,cutting,reaming and threading |

| Designs | 1.As per your drawings |

| 2.As per your samples | |

| Precision machining | Grinding machine group,milling machine group,CNC group,lathe group,EDM WEDM group |

| Surface finish | Polishing,sand blasting,heat treatment,powder coating ,anodizing , electroplating etc. |

| Features | 1.Inner insert can be removed from front,no need to dismantle the mold,more simple. |

| 2.Inner insert is replaceable,which can save cost. | |

| 3.Turn clockwise infinitely and smoothly,the surface does not have bump phenomenon with inscription. | |

| MOQ | 1 pieces |

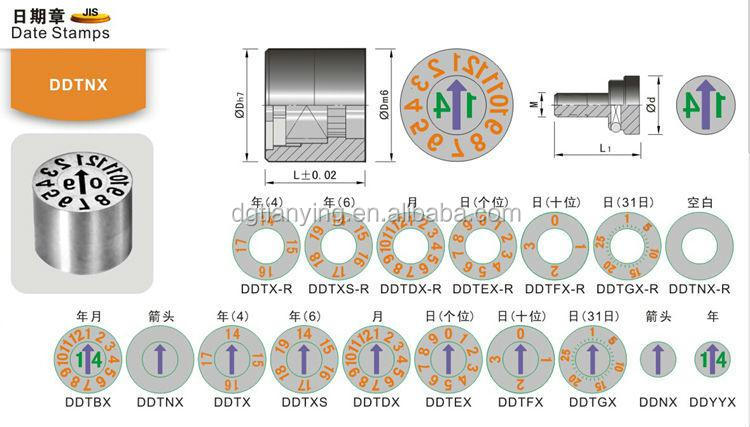

What are the detailed structures about date code insert?

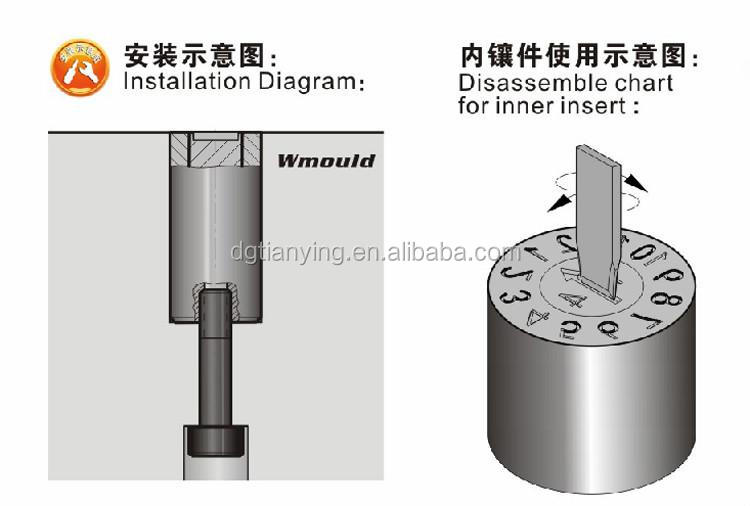

How to install the date code insert?

1.Strike date code insert into hole with rubber hammer.(Small hole will stop the inner from rotate,tear down inner insert before install,if need tear down the whole date stamps need keep the hole which is drive out by back side before install)

2.As right picture,rotate clockwise and anticlockwise inner insert to adjust the arrows to indicate the months.(use specified screwdriver to adjust)

More date time satmp for your choice.

How do you pack date code insert?

| 1.Each date code insert in plastic bag or fresco bag |

| 2.Wooden case and pallet,rust protection and suitable for shipment |

| 3.We can also pack as per your request |