| Packaging Details: | 25kg/bag,40bags/pallet Container transport |

|---|---|

| Delivery Detail: | 7 days after receiving the advanced payment |

Steel Shots and Grits Made in China-Largest Manufacturer

We are the biggest manufacturer of metal abrasive in China with over ten years experience.

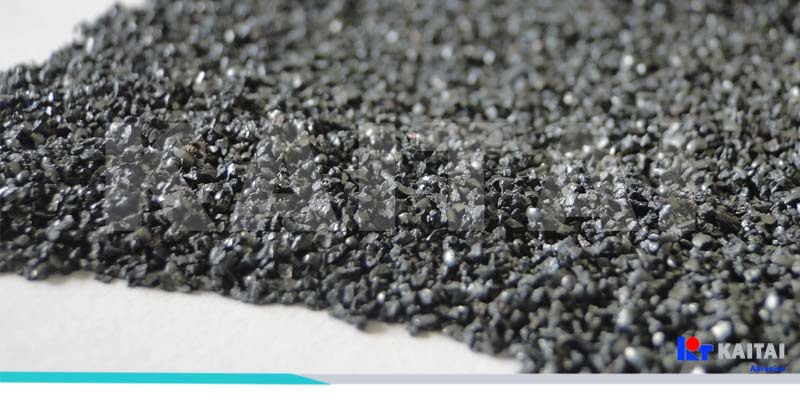

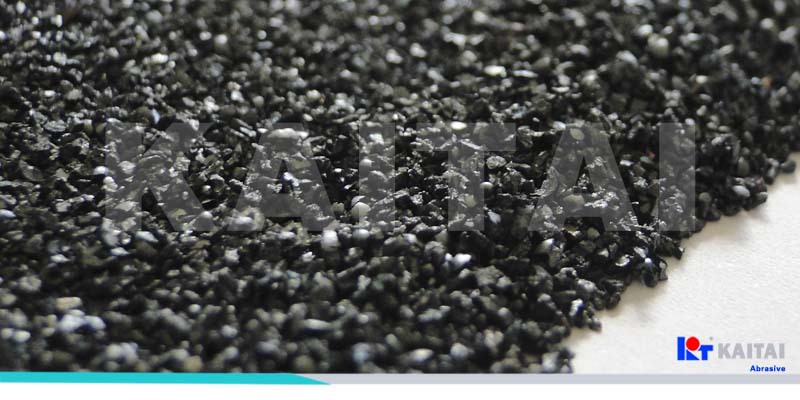

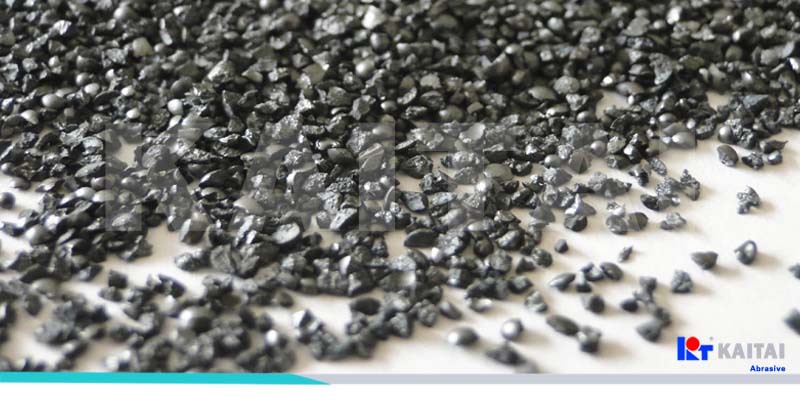

The size of Steel Shots and Grits:

G10,G12,G14,G16,G18,G25,G40,G50,G80,G120

Steel Shots and Grits Operative Standards:

In accordance with standards of GB/T18838.3-2008 Steel Shot and Steel Grit,SFSA20-66Cast Steel Abrasive, SAE J827 Cast Steel Shot, SAE J1993High Carbon Steel Grit, YB/T5149-1993 Cast Steel Shot, YB/T5150-1993Cast Steel Grit,ISO11124-3High Carbon Cast Steel Shot and Grit.

The Major Technological Index of Steel Shots and Grits :

|

Products |

Steel Shots and Grits |

|

|

Chemical Composition

|

C |

0.80~1.20% |

|

Mn |

0.35~1.20% |

|

|

Si |

≥0.40 |

|

|

S |

≤0.05% |

|

|

P |

≤0.05% |

|

|

Microhardness |

GP:42-52 HRC GL:53-60 HRCGH:60-64 HRC |

|

|

Hardness Deviation |

Max Deviation ±3.0HRC |

|

|

Microstructure |

Tempered Martensite or Sorbite |

|

|

Density |

7.6 g/cm3 |

|

Steel Shots and Grits Types:

GP:Angular when new, this grit rapidly rounds off in use and its particularly suited descaling applications.

GL:Although harder then GP steel grit, also loses its sharp edges during shto basting and is particularly suited to descaling and surface preparation applications.

GH:Having maximum hardness, GH always remains angular in its operating mix. These abrasive are particularly effective in surface treatment processes and produce a uniform, etched finish, GH angular grit should only be used in wheel machines where working requirements take precedence over cost price considerations (for example with rolling mill cylinders or when a special finish is needed). For use mainly with compressed air equipment.

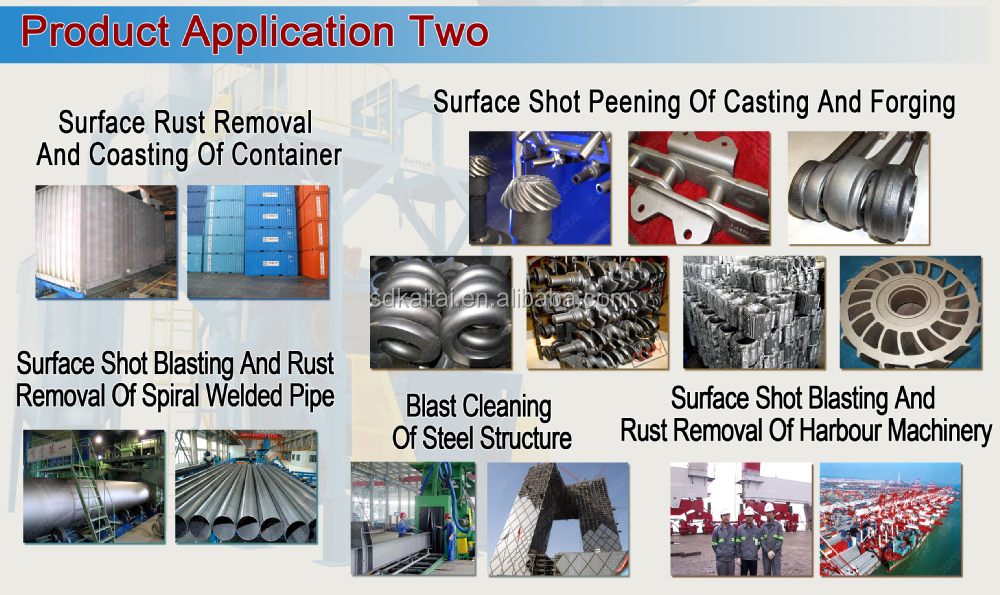

Steel Shots & Grits Application Devices:

Steel shots and grits mainly used for the following equipment including rotary barrel shot blasting machine, chain type shot blasting machine, pedrail type shot blasting machine,pass_through shot blasting machine,table type shot blasting machine Pendent-chain & Pile-type Shot Blasting Machine, trolley type shot blasting machine,abrator, abrator equipment, shot peening machine,shot peening equipment,sandblasting machine,sandblasting equipments,steel material pretreatment production line,steel plate pretreatment production line, steel structure pretreatment production line.

Blast cleaning of steel shots and grits :Used for blast cleaning of casting, die-casting,forging,sand removal of casting, steel plate , H type steel, steel structure.

Rust removal of steel shots and grits:Rust removal of casting, forging, steel plate, H type steel , steel structure, descaling of forging.

Shot peening of steel shots and grits :Shot peening of gear, heat treatment.

Shot blasting of steel shots and grits :Shot blasting of profile steel,ship board,steel board,steel material.

Shot blasting of steel shots and grits :Shot blasting of steel board, profile steel, steel structure.

Pre-treatment of steel shots and grits Pre-treatment of surface, steel board, profile steel, steel structure,before-painting.

General Packaging :

♥ 25kg per bag ,40 bags in one pallet

♥ 25kg per bag ,40 bags in one jumbo bag

♥ 25kg per paper bag ,40 bags in one plywood pallet

♥ One ton a bulk bags

♥ According to customer requirements

Shipping: Container transport

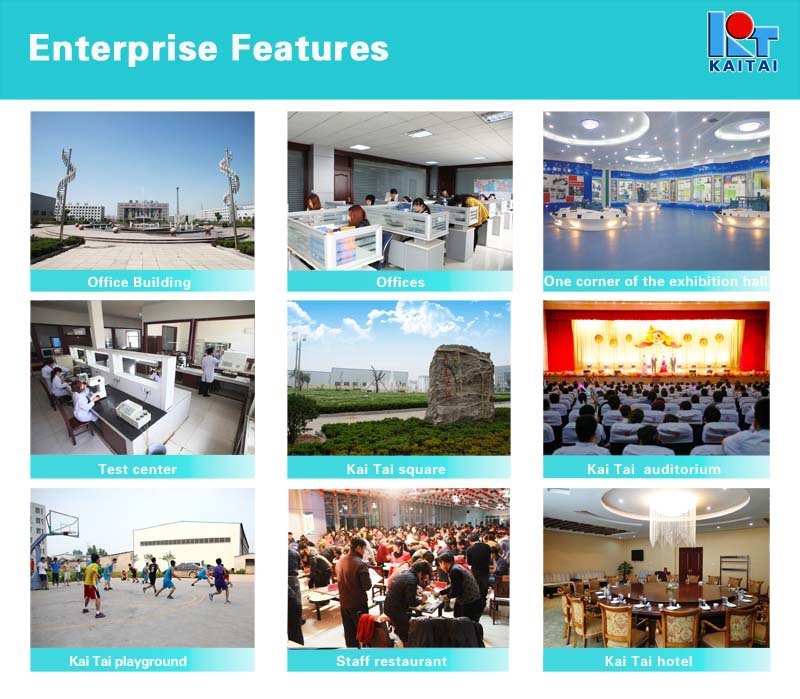

Shandong Kaitai Industrial Technologies Co., Ltd. is the biggest manufacturer of metal abrasive in Asia which integrates with technical research, development and production. Cooperating with Material Science & Engineering College of Shandong University and guided by experts and professors of metal abrasive field.

♥ The company has developed 8 series including cast steel shot, cast steel grit, steel cut wire shot, stainless steel shot, stainless steel cut wire shot, aluminium shot, zinc shot, copper shot, 80 kinds of abrasive products. The company could produces 250,000 tons metal abrasive.

♥ The company is Advanced & New Technology Enterprise of Shandong Province and National Blasting & Peening Standardization Technology Committee Unit. With strong technical force, advanced equipments like intermediate frequency induction furnace, centrifugal blasting machine and so on. The company could produces high strength, strong durability cast steel shot, cast steel grit through double quenching, tempering, screening and so on.

♥ The company has perfect quality control system. The company has introduced two Ervin Test Machine from USA. Ervin Test Machine is mainly used for testing fatigue life of metal abrasive. In additional, the company also has introduced SPECTRO spectral analyzer from Germany to test ingredient of metal abrasive. The quality of products has met SAE & ISO internationalstandards and the company has passed international standard ISO9001.

♥ The products have exported to more than 20 countries and regions and have got good comments from domestic and abroad users of foundry plant, forging plant, heat treatment shop, steel structure plant, container manufacturer, shipyard, auto and locomotive manufacturer and stone industries.

Q: Could you tell me your company payment term?

A: General 100% T/T in advance ,30% T/T in advance ,70% payment against copy of Bill of Loading ,100% L/C at sight

Q: What’s the MOQ do you carrying out?

A: We accept MOQ 500kgs normally. If you need less, you can contact us, we will see if it is OK.

Q: Can you provide free samples?

A: Yes,can forward free samples less than 200gs if possible.

Q: What standards are you carrying out for your products?

A: Our products reach SAE standard. We produce according to the ISO9001 and ISO14001 rules.

Q: To which countries and regions are you exporting pls?

A: About 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: What’s your year productivity?

A: We have three automatic production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Our yearly productivity: 250 thousand tons. So we can make delivery very fast.