Potassium Monopersulfate Used in Pharmaceutical

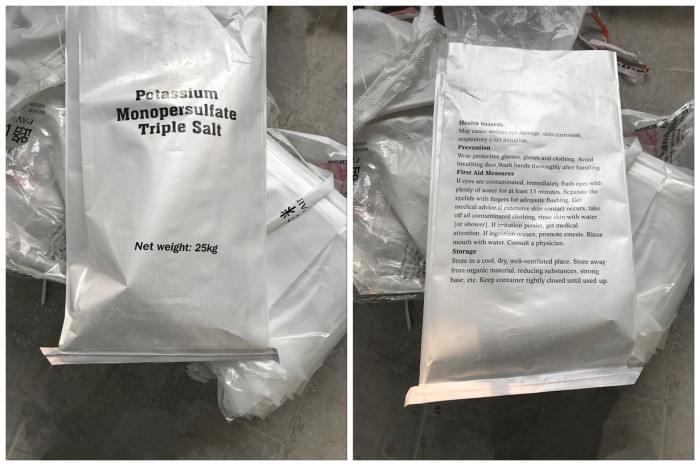

Potassium Monopersulfate compound is a kind of acid oxidant, a free flowing white granularly powder, and soluble in water.Other Names are Potassium peroxymonosulfate, potassium monopersulfate compound, Potassium hydrogen sulfate, PMPS, KMPS, ect.

Molecular Formula: 2KHSO5•KHSO4•K2SO4

Molecular Weight: 614.7

CAS NO.: 70693-62-8

Packaging: 25Kg/ PP Bag.

| Reactive oxygen species % | ≥4.5-4.9 |

| Active ingredients (KHSO5) % | ≥42.8-46 |

| Bulk density g/ml | 0.8-1.2 |

| Moisture % | ≤0.15 |

| Through the United States screening #20,% | 100 |

| Through the United States screening #200,% | ≤8 |

| PH value (25°C) 1% aqueous solution | 2.3 |

| PH value (25°C) 3% aqueous solution | 2 |

| Solubility(20°C) g/L | 256 |

| Stability, % reactive oxygen loss/ month | <1 |

| Standard potential (E°) V | -1.44 |

| Thermal conductivity, W/m | 0.161 |

Two effects of potassium peroxymonosulfate

1. DisinfectionIn the course of the disease, the farmers use many kinds of poison, but they still can not cure the disease. The main reason is that the use of the same disinfectant for the long time leads to the resistance of the pathogenic bacteria. Therefore, in the fish and shrimp refractory disease can not be a good treatment, you can try two consecutive use of potassium peroxymonosulfate products, can kill chlorine or surface active agent and can not kill the pathogens.For the prevention of Vibrio, bleeding and other diseases,potassium peroxymonosulfate have a better effect, and will not make the original pathogen resistance.The main field of application in livestock care disinfection, disinfection, disinfection, spa pool dentures family disinfection.

2. Water quality improvementPeroxymonosulphate can not only kill algae and other plankton, but also can eliminate algae and other biological toxins. Pond culture, the water that is the life of the water field, but also feces, bait and other garbage disposal sites. In particular, the breeding density is too high, the water self-purification capacity is limited, water quality often abnormal, such as black water pumping, thick green water, algae and other conditions. Potassium peroxymonosulfate has strong oxidizing properties, can supplement the lack of active oxygen in water, while oxidation due to insufficient accumulation of organic matter, ammonia, sub-salt, hydrogen sulfide and other harmful substances, to achieve the purpose of water quality control. The main application areas aquaculture water improvement, life industrial wastewater treatment, and hospital water treatment,etc.