Basic Company Information

Nanyang Goodway Machinery & Equipment Co., Ltd.

Nanyang Goodway Machinery & Equipment Co., Ltd.

TEL : 86-6745-6228 / FAX : --

Erlangmiao Street, FangCheng County, NanYang City, HeNan Province, China HeNan NanYang China [CN]

Homepage : http://www.goodwaychina.com

Main Products

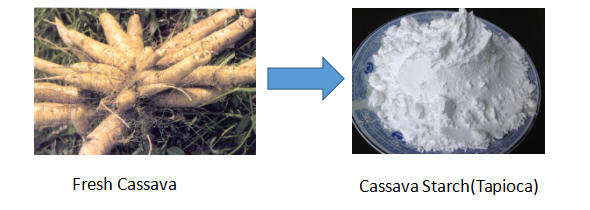

cassava starch proc , , , ,

Company Advantage

Specialized in industrial cassava & potato processing machineries from China

Detail Company Introduction

Nanyang Goodway Machinery & Equipment Co., Ltd. is a leading manufacturer and supplier of Cassava & Potato Processing Machineries, focus on providing the system solutions in the fields of Cassava Starch, Potato Starch, Sweet Potato Starch, Cassava and Yam Flour, Garri/Gari, Fufu Flour, Cassava Chips processing since 1991 in the worldwide.

Trade Information

Total Annual Sales Volume

US $2.5 Million - US $5 Million

Export Percentage

31% - 40%

Accepted Delivery Terms

FOB , DEQ

Accepted Payment Currency

USD

Accepted Payment Type

T/T , L/C