Diamond bruting wheel is used for polishing and bruting natural diamond. It can substitute PCD (polycrystalline diamond) and possess excellent diamond processing performance. Diamond bruting wheel has been proved its superiority in the jeweler processing industry, since it has enjoyed wide popularity in South Africa, Hong Kong, India, Belgium, Israel market, and etc.

Applications of diamond bruting wheels

Diamond bruting wheel is installed on advanced CNC bruting machines, widely used for polishing and bruting natural diamonds, gemstone, jewel, agate.

The advantages of diamond bruting wheels

* Compared with resin bond wheel and metal bond wheel, vitrified diamond bruting wheel could process at least 2 to 3 times products at the same time.

* not easy to jam and burn the workpiece, good self-sharpening, easy dressing and long life .

* High abrasive resistance and abrasive wear is small.

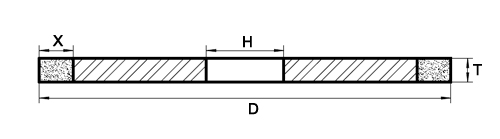

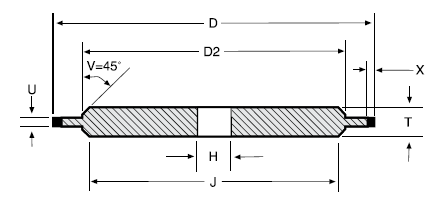

Specifications of diamond bruting wheels

|

Model

|

D (mm)

|

T (mm)

|

H (mm)

|

X (mm)

|

U (mm)

|

|

1A1

|

80

|

10

|

32

|

8, 10

|

|

|

150

|

10

|

32

|

10

|

|

|

155

|

10

|

32

|

10

|

|

|

160

|

10

|

32

|

10,12

|

|

|

170

|

10

|

32

|

10, 12, 14

|

|

|

175

|

10

|

32

|

10

|

|

|

220

|

10

|

32

|

20

|

|

|

14A1

|

170

|

10

|

32

|

10, 12, 14

|

5

|

|

175

|

10

|

32

|

10, 15

|

5

|

|

Grain size :MD20, MD40, MD60, MD80

MD-20: fine polishing,perfect shining performance and long life for polishing small diamond (10 points- 1carat)

MD-40, MD-60: rough polishing,high efficiency polishing and sharp cutting for big diamond.(1ct ,1.2ct and 1.3 carat,etc)

MD-80: rougher polishing, higher efficiency and sharp cutting for bigger stones.(2 carat and 3 carat,etc)

|

Application cases of diamond bruting wheel for natural diamond polishing:

*1A1 diamond bruting wheels have sent to Thailand and American clients

|

products name

|

1A1 170D * 32H * 14X * 10T, 1A1 175D * 32H * 10X * 10T

|

|

Workpiece

|

bruting and girdling natural diamond for all shapes

|

|

applicable machine

|

EOS bruting machine

|

The advantages of diamond bruting wheels

1.Compared with resin bond wheel and metal bond wheel, vitrified diamond bruting wheel could process at least 2 to 3 times products at the same time.

2. not easy to jam and burn the workpiece, good self-sharpening, easy dressing and long life .

3.High abrasive resistance and abrasive wear is small

Product description of vitrified bond diamond grinding wheels

1.Vitrified bond diamond grinding wheel possess pretty high abrasive resistance, especially in polishing hard and brittle workpiece.

2.Vitrified bond diamond grinding wheel has many advantages like small grinding force, low operating temperature, high grinding precision, excellent workpiece's surface grinding, etc.

3. Vitrified bond diamond grinding wheel recognized as a high performance grinding wheel with the higher speed, higher efficiency, higher precision, lower abrading cost and lower pollution.

4.Vitrified bond diamond grinding wheel is widely used in wafer, PDC, PDC, diamond cutter, CBN, cemented carbide, new engineering structural ceramic, diamond, jewel, crystal, rare earth materials and another hard-brittle materials' machining operation.

Production process of ceramic diamond grinding wheel:

1. Mix: the binders and diamond powder are fully stirred and fused in a certain proportion

2. Weighing: weighing according to the volume, ring width and density of the grinding wheel required by the customer

3. Feeding: put mixed diamond powder and binding agent into the grinding tool

4: compression ring (let stand for a period of time to wait for molding)

5: back mould

6: the abrasive layer is air-dried

Cook for 10 hours at 7:670 degrees

8: cooling (prepare the matrix at the same time)

9. Fixed decoration of the whole

10: measure stationarity

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasive diamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

1.Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

2. Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

3.Woodworking saw blade and tools .

4.Hss tools

5.Cutting wheels

|

Our product’s advantages:

1.High grinding efficiency

|

|

2.Wonderful edge quality

|

|

3.Long service life

|

|

4.High polishing efficiency

|

|

5.Large Exports

|

|

6.Considerable after-sell service

|

|

7.Amazing performance

|

|

8.Various types and sizes available

|

|

9.Direct Factory Manufacturer

|

|

10.Backing/substrate material: Aluminum

|

|

11.Abrasive layer: diamond

|

|

12.Bond: vitrified

|

|

13.Excellent cutting edges

|

|

14.Reduced cycle times

|

|

15.Custom Engineered

|

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

Alisa@moresuperhard.com

Tel:18638297665

URL:www.moresuperhard.com