Supply crankshaft repair, crankshaft wear laser cladding repair

Laser processing is an advanced manufacturing technology developed at the end of the last century. It is used in various fields such as machinery manufacturing, metallurgy, transportation vehicles, molds, petrochemicals, exploration, electricity, textile, aerospace and other fields. The main features of laser surface treatment products are: high hardness, high efficiency, good quality, and can achieve high abrasion resistance, high strength, high corrosion resistance, high red hardness and other properties that cannot be achieved by conventional techniques, and cannot achieve conventional methods. The heat treatment or repair method is achieved.

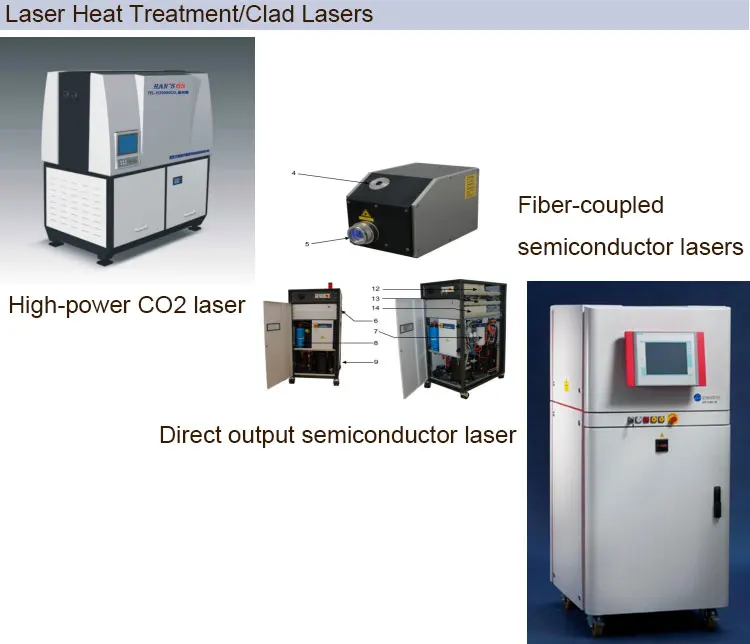

Laser processing technology mainly includes: laser surface transformation hardening (quenching) processing, laser cladding (repair) processing, laser surface alloying, laser melting, etc.

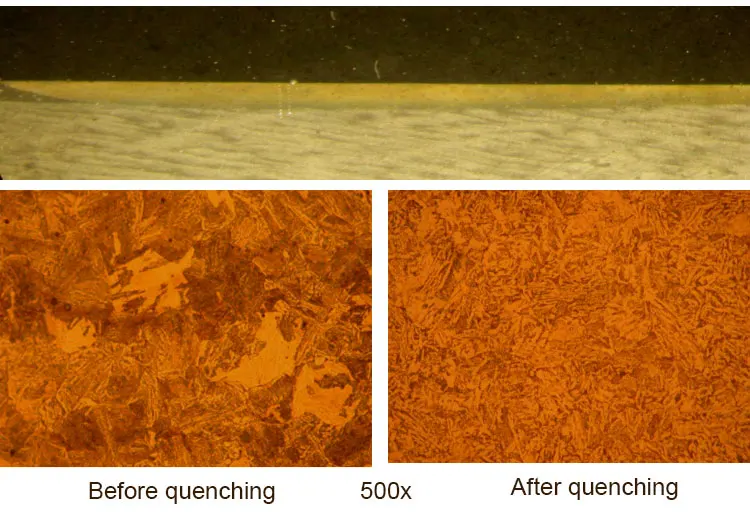

The advantages of laser quenching

Heating and cooling speed, quenching effect is good;The laser is hardened by heat conduction from the surface and inside, no cooling medium, no pollution to the environment.Self-tempering process, no need to temper, process is simple;Only heating the surface, the overall performance of the workpiece is not affected;Heating parts can be precisely controlled and easy to automate production;Specially designed light guide system can be used for quenching deep holes, inner holes, grooves, blind holes, etc.In the industrial field, traditional processes such as induction hardening and chemical heat treatment are gradually being replaced.

Anatomical Analysis of the Tooth Surface before and after Laser Quenching of Internal Ring Gear

SpecificationThe product is composed with TFL-6K/10K laser source, specific 60000 calories water chiller, CNC processing machine tool, auto powder delivery machine, optical path system and CNC control system.

| Model | GS-TFL-6K/10K | ||

| Laser source | TFL-6K/10K laser source/ semi-Laser source conductor laser source | ||

| Optical system | Fly optical path, Light path diameterφ70 | ||

| Manual type swing bald,Turning Angle±60°manual adjustment | |||

| CNC machine tools | |||

| model | 2 M | 2.5 M | 3.5 M |

| Working area (mm) | 2000*600*500 | 2500*1000*5000 | 3500*1000*500 |

| X, Y, Z axle working speed | 0 - 5000 m/min | ||

| Location accuracy | ±0.1 mm / 300 mm | ||

| Relocation accuracy | ±0.05 mm | ||

| Horizontal rotating table | |||

| Max. chuck diameter |

Three claw Φ500/centerheight 500mm |

Four claw Φ630/centerheight 690mm |

Four claw Φ630/centerheight 800mm |

| Rotating speed | 0.5 - 15 rpm | 0.05 - 5 rpm | 0.05 - 5 rpm |

| Platform size(mm) | 3860 * 1450 * 280 | 5560 * 1000 * 280 | 7000 * 1200 * 350 |

| Center shaft |

Bearing diameterΦ100-Φ350 one set |

Bearing diameterΦ370-Φ630 two set s |

Bearing diameterΦ370-Φ630 two set s |

| Max. Length of workpiece | 2500 mm | 3500 mm | 4000 mm |

| Max. Diameter of workpiece | Φ 800 | Φ 1350 | Φ 1500 |

| Max. Weight of workpiece | 5 T | 10 T | 15 T |

| Control system | Siemens Siemens 828D AC servo motor | ||

Laser Heat Treatment/Clad Lasers