Basic Company Information

Henan Doing Mechanical Equipment Co., Ltd

Henan Doing Mechanical Equipment Co., Ltd

TEL : 86-371-56771823 / FAX : --

NO.133, Yaozhai Road,Jinshui District Henan Zhengzhou China [CN]

Homepage : http://www.doinggroup.com

Main Products

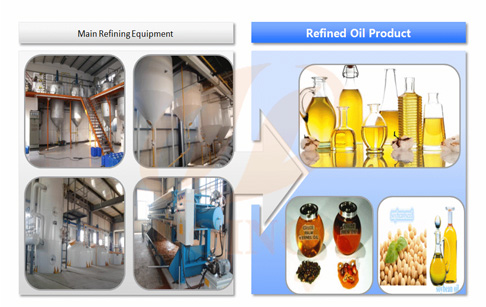

oil pressing machine , solvent extraction , oil extraction plant , oil refinery plant , palm oil machine

Company Advantage

Henan Doing Mechanical Equipment Co.,ltd is specialized in researching and developing technology of Oil Extraction, Oil Refinery & Fractionation since 1967. Doing is one of the leading manufacturer of oil processing equipment in China.Our company service includes:technology design,installation and commissioning,technical training,relocation of oil plant,technology reform and turnkey project.

Detail Company Introduction

Henan Doing Mechanical Equipment Co.,ltd located in Henan Province, is a main producer of oil

equipment in China and a unit exempt from quality examination.

Our company has a research institution which develops new products with our experiment basis and

an integrative joint-stock production company of oil and electromechanical engineering, production

and installation. We continue to introduce foreign talents, renew products and take the leading

position in this field.

Our products have passed ISO9001 international quality system management cortication. Our company

has got the title of "bank grade AAA enterprise". Our company covers 99000m2 and has fixed assets of

RMB50 million. We have 480 staff members, of whom 6 senior engineers, 22 engineers and more than 70

installation workers with rich experience. We have had good cooperation with Beijing Science and

Technology University, Sian Oil Science Research Institution, Zhengzhou Industry College and other

authorized research agencies. We use CAD design system and our special use software to design works.

We supply comprehensive and highly utilized vegetable oil plant with general design and also special

designs, the first-class technology and service. We also can supply various levels of technology

designs and services according to customer's requirements. We insist on the tenet of "quality first,

customer superior", supplying customers with perfect technology consultation and high-quality

after-sales services.

We have advanced processing equipment and scientific management systems. Our products sell well

in 28 provinces and cities in China and are exported to central Asian countries, like Uzbekistan,

Kyrgyzstan, Kazakhstan and other more than 10 countries and areas, like Canada, Chile, Argentina,

Ethiopia, Zambia, Nigeria, Russia and Turkey. We also have offices in Urumqi, Xinjiang, Uzbekistan

and other countries and regions.

Business scopes:

1-2000tpd pre-treatment and pressing workshop,

30-2000tpd cooking oil solvent extraction production line,

1-600 tpd refining workshop,

palm oil/palm kernel oil mill plant

And we offer both production line and single machines.

Our services

Technology design, installation, debugging, technical training, oil plant relocation, technology

reform and turnkey projects

After-sales service tenet

Creative is fortune; improvement is development.

Doing performs the competition by high quality services and advanced technology, insists on the

policy of "safety, high effect, low consumption" and follow the principles of "quality first,

service superior". We are well praised and trusted by clients from at home and abroad.

Factory Information

Factory Location

Factory Address

Wuzhi County,Jiaozuo city,Henan Province,China

Factory Size

50,000-100,000 square meters , Above 50 People

No. of R & D Staff

Above 50 People

No. of Production Lines

Above 10

Annual Output Value

US $10 Million - US $50 Million

Trade Information

Total Annual Sales Volume

US $10 Million - US $50 Million

Export Percentage

91% - 100%

Accepted Delivery Terms

FOB , CIF , EXW

Accepted Payment Currency

USD

Accepted Payment Type

T/T , L/C , D/P D/A