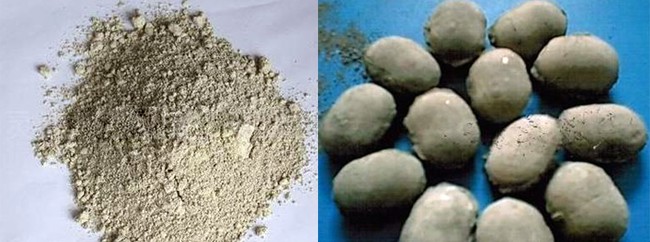

Dry powder briquette machine is based on the direction of development of domestic and foreign counterparts,collect the advantages of similar powder briquette,machine, make full use of advanced technology to develop a new generation of products. Pressure roller adopt wear-resisting alloy forged, bearing with bearing series mill,spindle uses large diameter 40Cr after forging, quenching and tempering, the hydraulic system by the formal large matching. Dry powder briquette machine is mainly used for anhydrous materials of non-ferrous and ferrous mineral powder briquette /ball making system before the smelting furnace, such as coal, coke powder, coking coal, coal ash, coal mud, iron ore concentrates, chromate ore concentrates, mgo power, copper power, chrome ore power, and so on.

1. High yield of finished products.

2. Cycle operations to achieve continuous production.

3. Without any additives, dry powders are briquetted directly.

4. Briquetting strength can be adjusted by adjusting the pressure of roller, control strength of final products.

5. Control environmental pollution, reduce waste and powder packaging costs, and improve product transport capacity.

6. Materials are force to compress molding by mechanical pressure, without any additives, the product’s purity is guaranteed.

7. A wide range of raw materials can be used, granular strength can be freely adjusted according to different materials.

8. Compact structure, easy maintenance, simple operation, short process, low energy consumption, high efficiency, low failure rate.

9. Dry powders are briquetting directly without follow-up drying process, the existing production process is easy to convergence & transformation.

10. Feeding device adopts frequency adjustment control, high automation, one can control multi-machine, has the features of low labor intensity and long term continuous operation, etc.

11. Multi-functional High Quality Dry Powder Briquette Machine/High Quality Dry Powder Ball Briquette Machine strength is high, compared with other granulating methods, the improvement soft bulk density are significant, especially for the occasion where increase the proportion of product accumulation.

12. Major transmission components use high quality alloy material. Stainless steel, titanium, chromium and other surface alloys which greatly improved wear resistance, corrosion resistance, high temperature and pressure capabilities, so that this machine has one long service life.

Henan Fote Heavy Machinery Co., Ltd. is a Chinese specialized manufacturing enterprise incorporating the research, development, production and sale of top quality dry powder briquette maker, slurry briquette machine, lime briquette machine, gypsum briquette machine, hydraulic briquette machine, coal ash briquette machine and so on. If you are interested in briquette machinery, welcome to contact or visit Fote Machinery.

Contact Information

Email: info@sinoftm.com

Website: http://www.foteinfo.com/dry-powder-briquetting-machine-48.html

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China